What We Do

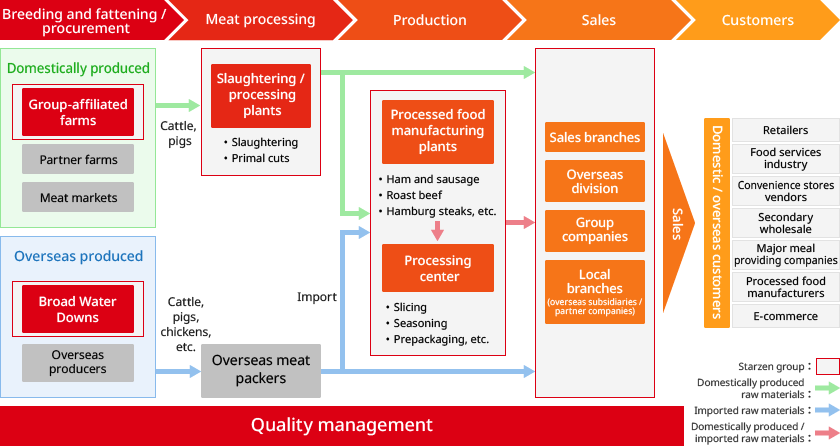

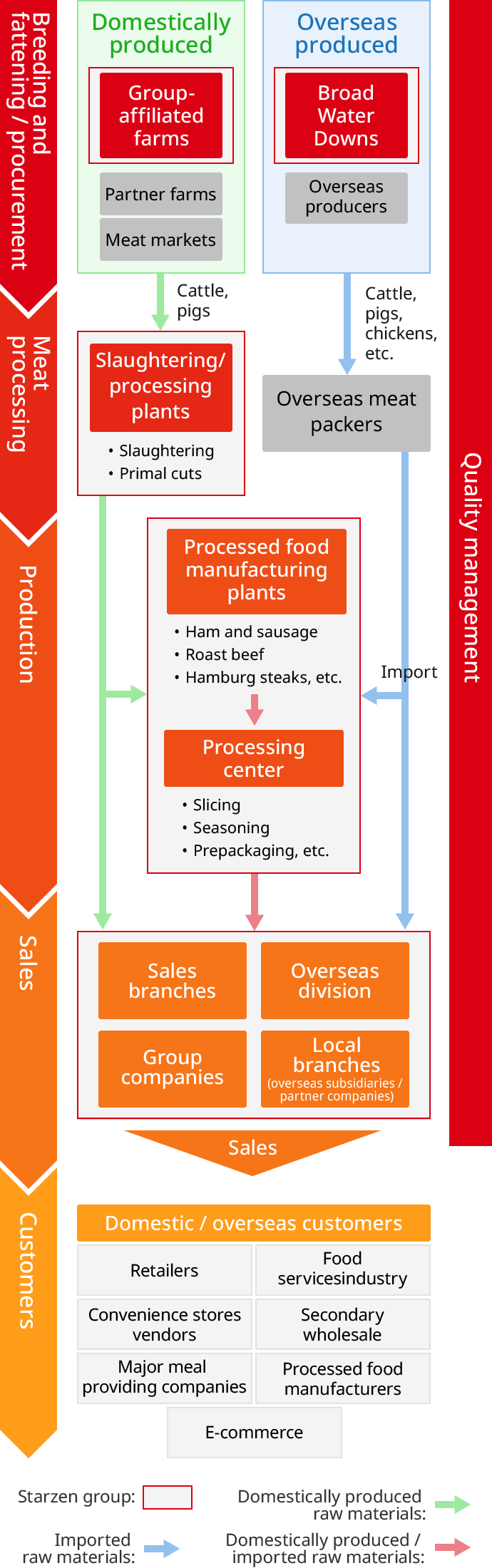

We have built a comprehensive supply chain which includes everyone from producers to customers.

This enables us to supply safe, high-quality meats and processed foods.

Breeding and fattening

Domestic breeding and fattening

We operate Group-affiliated farms at our main livestock production sites. We undertake breeding and fattening of cattle and pigs under strict hygiene controls at each farm, and in doing so support a stable supply of these products. Furthermore, leveraging the strength of having our own cattle and pig farms, we produce branded beef and pork that offers a high level of added value to meet the needs of the market. As part of our efforts toward building a sustainable livestock business, we are also utilizing eco-friendly feed and undertaking initiatives based on the idea of animal welfare among other such actions.

Furthermore, in order to tackle the issues of instability in roughage imports and soaring prices, we are also working on our grassland business. By expanding production capacity for domestically-produced roughage, we are working to achieve stability and reduce costs.

Furthermore, the decline in the number of farmers breeding domestically-produced cattle, including Japanese Wagyu cattle, is an issue that has become increasingly serious over recent years, and we are working to help strengthen the production base by cooperating with dairy farmers to increase the number of calves produced from fertilized Wagyu cattle embryos, thereby contributing to solutions for challenges faced by industry as a whole.

Overseas breeding and fattening

Having acquired an Australian feedlot as a subsidiary, we are working on breeding and fattening Australian Wagyu cattle for the Chinese and Southeast Asian markets. In a rich natural environment on a scale equivalent to 1,500 Tokyo Domes (an indoor baseball stadium in Tokyo), the company carefully fattens cattle in a stress-free environment, and raises them lovingly to provide Australian Wagyu with a high, stable quality.

Our employees take responsibility for managing each stage of the process, from fattening to processing into meat for consumption, and by leveraging the knowledge and know-how of the Japanese Wagyu beef producer in Japan with whom we have a capital alliance, we will provide a stable supply of our own high-quality Australian Wagyu.

Procurement

Domestic procurement

In addition to Group-affiliated farms, we have created robust partnerships with partner farms in Hokkaido, Tohoku, Kyushu, and other locations around Japan, and have put in place a stable procurement infrastructure for domestically-produced cattle and pigs. We also continuously work to build trusting relationships with livestock producers by holding regular carcass training sessions with producers, manager meetings, farm visits, and other such events. And by having a broad collection network, we have established a system with the ability to maintain a stable supply in the event of an emergency, such as a disease outbreak or natural disaster.

We procure domestically-produced chicken from partner companies and affiliates. We also undertake joint activities with them such as the development of processed products, implementing initiatives that leverage our partnerships.

Overseas procurement (import)

Since we commenced imports of beef from Australia in 1955, Starzen has built up long-term partnerships with local meat packers in areas including the United States, Canada, the EU, Brazil, and Thailand, and has worked on the stable supply of high-quality beef, pork, and chicken.

We leverage our broad procurement network to import a range of beef and pork cuts from various countries to Japan, mainly for retailers, the food services industry, and processed food manufacturers. We are also investing resources in the development of original brands in collaboration with packers, while working on long-term grain-fed beef and branded pork carefully produced from selected pig breeds raised on special feed.

Starzen mainly imports chicken from Brazil, Thailand, and the United States chiefly for processed food manufacturers, the food services industry, commercial wholesalers, and retailers.

Furthermore, on the back of tariff reductions provided by Economic Partnership Agreements, we are actively importing foreign-produced primary-processed products (sliced products) and secondary-processed products (cooked products). As well as proceeding with product development suited to the Japanese market in partnership with packers in each country, we prioritize safety and security and implement quality management at processing plants.

Meat Processing

We have seven plants with slaughterhouses near production areas in Hokkaido, Tohoku, Kanto, and Kyushu. The advantage of a plant with a slaughterhouse near production areas is that the meat can be processed without exposure to outside air. We place the utmost importance on creating a system to ensure the delivery of fresh, high-quality products. All seven plants have obtained international Safe Quality Food (SQF) certification for food safety and quality.

We provide safe, reliable, high-quality processing of beef, pork, and variety meats. Taking advantage of the fact that we own our plants, we also provide meticulous support, including processing according to customer specifications. To address labor shortages, we are promoting mechanization and automation. We introduced bone removal robots, ahead of the rest of the industry. Furthermore, each plant has been certified by the Ministry of Health, Labour and Welfare as an export facility. This allows us to export to 51 countries and regions at present, including the United States and the EU, which have strict standards for exports.

We have seven plants with slaughterhouses near production areas in Hokkaido, Tohoku, Kanto, and Kyushu. The advantage of a plant with a slaughterhouse near production areas is that the meat can be processed without exposure to outside air. We place the utmost importance on creating a system to ensure the delivery of fresh, high-quality products. All seven plants have obtained international Safe Quality Food (SQF) certification for food safety and quality.

We provide safe, reliable, high-quality processing of beef, pork, and variety meats. Taking advantage of the fact that we own our plants, we also provide meticulous support, including processing according to customer specifications. To address labor shortages, we are promoting mechanization and automation. We introduced bone removal robots, ahead of the rest of the industry. Furthermore, each plant has been certified by the Ministry of Health, Labour and Welfare as an export facility. This allows us to export to 51 countries and regions at present, including the United States and the EU, which have strict standards for exports.

HAMDAS-RX automated deboning machine for pork ham

Production of Processed Meats

We utilize raw materials sourced in-house to manufacture processed meats such as ham, sausages, bacon, roast beef, roast pork, and hamburgers. In addition to production under our own brand, we produce products according to customer specifications. Our products are also widely adopted in popular menu items, including beef patties for a major hamburger chain and dishes like hamburger steaks and roast beef for large casual dining restaurant chains.

We also have processing centers all over Japan to address the recent labor shortage. These processing centers produce prepackaged delicatessen items including sliced meat and roast beef salads, thus helping retailers such as mass retailers and supermarkets reduce backroom workload while also contributing to reduced food waste through longer best-before dates.

Sales

Domestic sales

We have about 50 sales offices throughout Japan, from Hokkaido to Kyushu, and sell our products to various customers, including town butchers, emporiums, supermarkets, convenience stores, food service companies, and food manufacturers.

Our strength lies in our face-to-face sales, delivering products directly via our own trucks. This enables us to identify customer needs and market trends early on.

Based on the motto of sticking close to our customers, we work across divisions to solve customer problems as Team Starzen in order to ensure that they are happy working with us.

We have about 50 sales offices throughout Japan, from Hokkaido to Kyushu, and sell our products to various customers, including town butchers, emporiums, supermarkets, convenience stores, food service companies, and food manufacturers.

Our strength lies in our face-to-face sales, delivering products directly via our own trucks. This enables us to identify customer needs and market trends early on.

Based on the motto of sticking close to our customers, we work across divisions to solve customer problems as Team Starzen in order to ensure that they are happy working with us.

Overseas sales

In September 2009, the Akune Plant became a certified facility for the export of meat to Macao, marking the full-scale start of Japanese Wagyu beef exports. Currently, we have been able to export Japanese Wagyu beef, pork, and other products to 51 countries and regions, including Taiwan, Hong Kong, the United States, EU, Singapore, Thailand and Canada.

As an initiative to expand our export business, we are working on collaborations with local meat businesses in each export area, and are providing a wide range of products to sectors including the food services industry and retail, from prime cuts such as loin and fillet to shoulder and round meats.

Furthermore, by offering customized specifications, pre-slicing, vacuum seal packaging, and other such variations in our products, we ensure ease of handling for our customers. And in doing so, we are making Japanese meat a presence throughout overseas markets.

We are also investing resources in the export of processed foods, and undertaking sales of hamburg steaks, roast beef, and sausages for the retail sector and food services industry.

To meet the growing demand driven by the global popularity of foreign-produced Wagyu, we are strengthening sales of our original high-quality Australian Wagyu brands, Imperial Blossom Beef and Eight Blossom Beef. From Australia, we export mainly to China, Hong Kong, and Southeast Asia, supplying retailers, trading companies, food wholesalers, processors, and other customers.

In addition, by leveraging our strong procurement and supply capabilities, we are actively engaged in trilateral trade, supplying beef, pork, and offal from countries such as Australia, the USA, Canada, and Brazil to consumer markets around the world.

To meet the growing demand driven by the global popularity of foreign-produced Wagyu, we are strengthening sales of our original high-quality Australian Wagyu brands, Imperial Blossom Beef and Eight Blossom Beef. From Australia, we export mainly to China, Hong Kong, and Southeast Asia, supplying retailers, trading companies, food wholesalers, processors, and other customers.

In addition, by leveraging our strong procurement and supply capabilities, we are actively engaged in trilateral trade, supplying beef, pork, and offal from countries such as Australia, the USA, Canada, and Brazil to consumer markets around the world.

Through Starzen’s six overseas sales offices and our partner companies, we sell meat products, including Japanese and Australian Wagyu beef, and processed meat products around the world. By leveraging our Japanese Wagyu knowledge, skills, cut techniques, and other such assets to provide value from the perspective of local customers through our interdepartmental “Team Starzen”, we have been able to build relationships of trust.

In Southeast Asia, we also sell meat through e-commerce and run sales outlets in Japanese department stores, thereby identifying consumer needs and working to grow sales.

Furthermore, through Starzen’s procurement infrastructure for raw materials from domestic and overseas sources and collaborations with local partners, we support the overseas expansion of Japanese companies.

Quality Control

At the Starzen Group, we are promoting the acquisition of international Safe Quality Food (SQF) certification for ensuring food safety and quality in order to deliver products that our customers can enjoy with peace of mind. So far, the certification has been obtained at more than 50 of our business locations.

We practice safety and quality control in accordance with SQF at all of our business divisions and sites, from processing and production to distribution and sales. We also use the principles of SQF as a guide for safety and reliability as we work on continuous improvement in tasks such as daily cleaning activities, labeling and packaging, chemical management, and employee training.